Perfect for Offshore Applications

The coated stainless steel ties provide excellent corrosion resistance for our offshore installations. The protective coating withstands harsh marine environments perfectly.

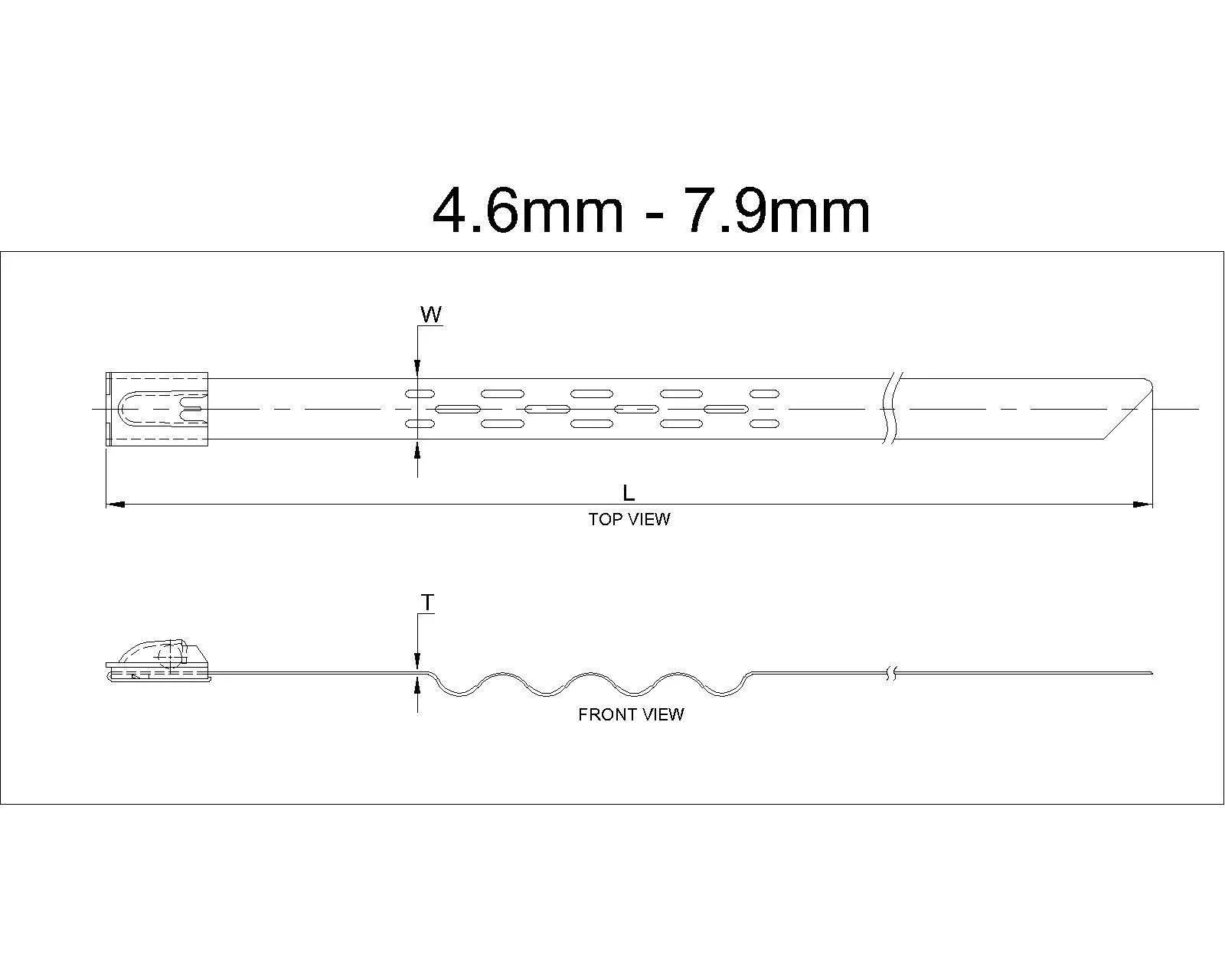

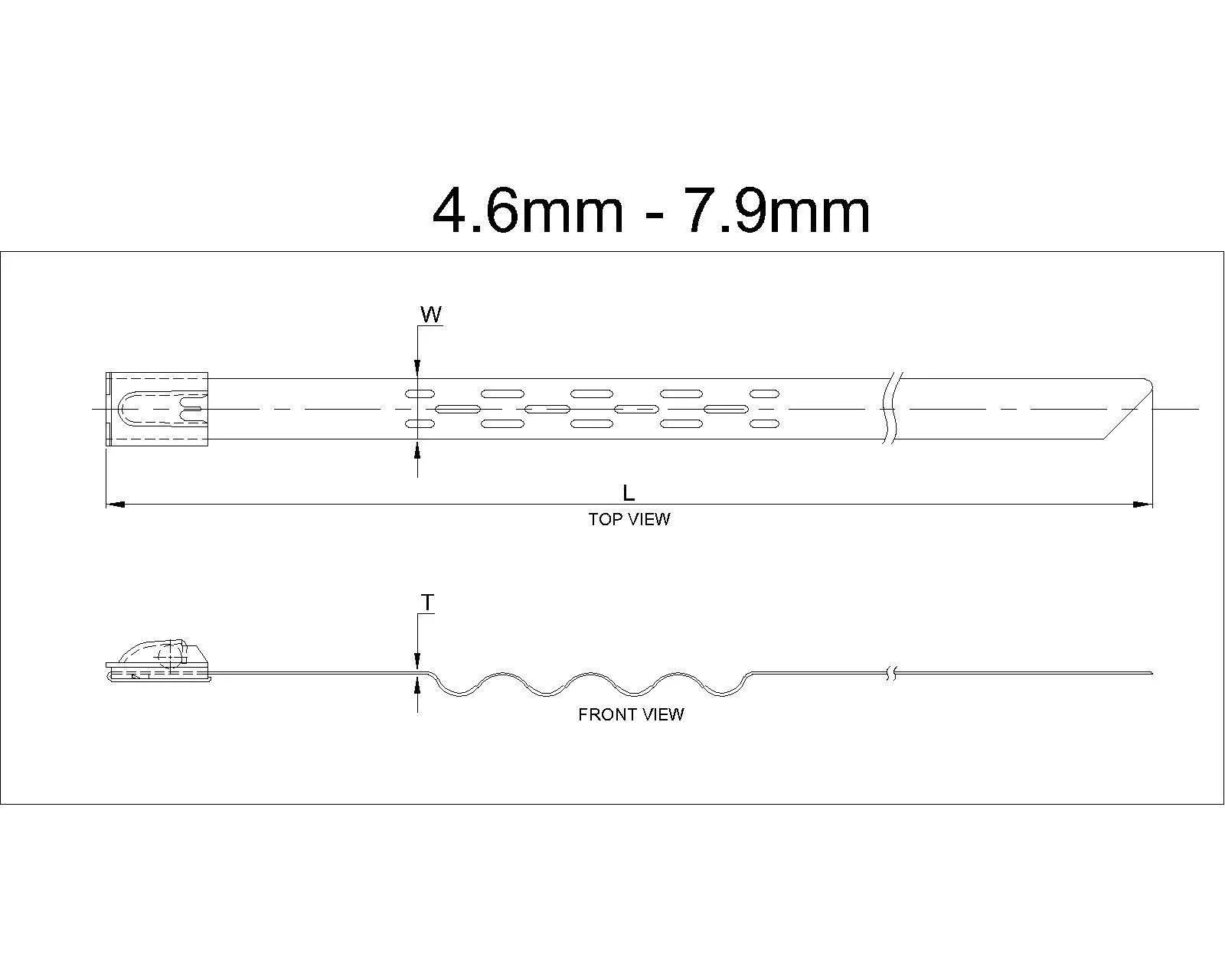

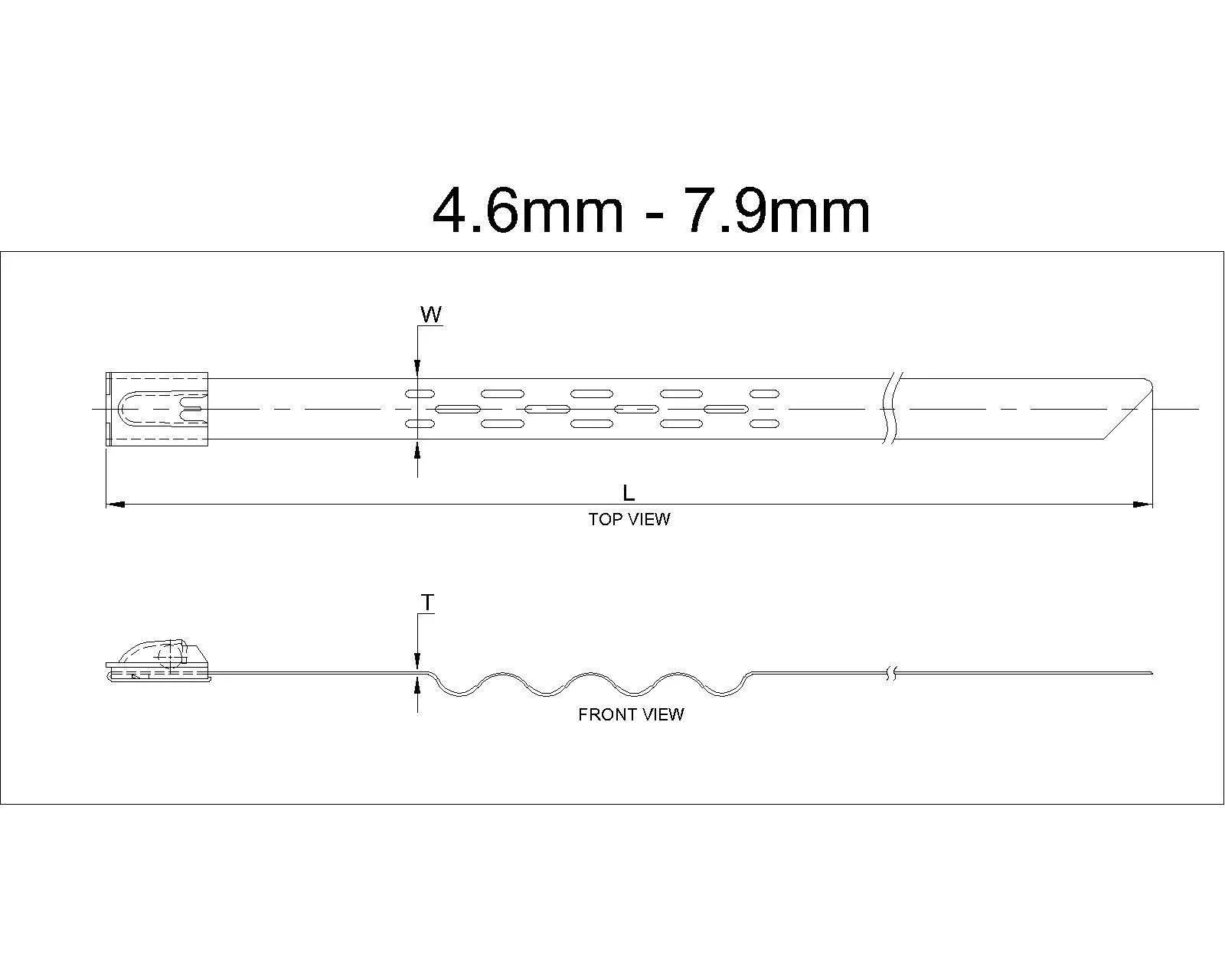

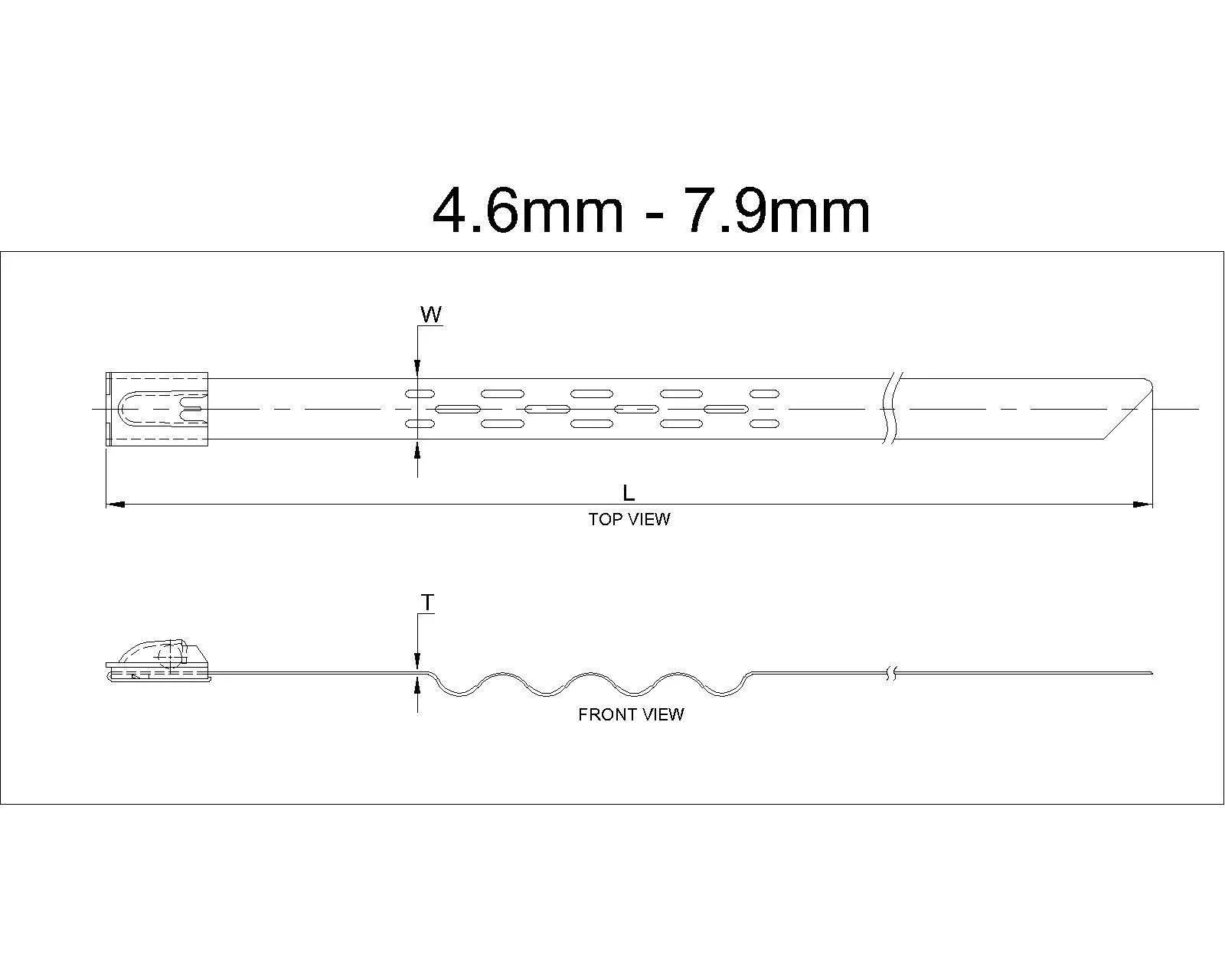

Ball Lock Zigzag Tie Coated

Price Available on Request

Comprehensive range of Ball Lock Zigzag Tie Coated with varying lengths, widths, and tensile strengths for diverse wire bundling applications.

Unique modified wave form design clamps where no other steel ties retain tension, providing superior holding power in high-vibration environments.

Grips firmly on solid objects at low applied forces, ensuring secure cable bundling even with minimal installation tension.

Smooth edges of ties provide utmost safety while installation, reducing the risk of injury during handling and application.

Non-toxic, halogen-free, low smoke coating material with exceptional UV resistance for long-lasting outdoor performance.

Coated stainless steel construction provides long-term life in corrosive climate conditions including marine and offshore environments.

Operating temperature range from -80°C to +150°C ensures reliable performance in extreme environmental conditions from arctic to desert climates.

Subscribe to receive our latest product updates and technical specifications directly.

For indoor cable bunching and durable locking in adverse conditions like humidity, heat, cold, vibration & external shocks.

The coated stainless steel ties provide excellent corrosion resistance for our offshore installations. The protective coating withstands harsh marine environments perfectly.

Operations Manager, Offshore Oil & Gas

We use these coated steel ties in extreme temperature conditions from -60°C to +130°C. The coating remains intact and the ties maintain their strength throughout.

Project Lead, Solar Energy Systems

The smooth edges on these coated ties make installation much safer for our technicians. Combined with the STT tools, the installation process is fast and reliable.

Installation Supervisor, Telecom Infrastructure

The 12mm heavy duty series with 111kg tensile strength is perfect for our wind turbine cable management. They handle the constant vibration without any issues.

Maintenance Manager, Windmill Energy

Having both SS 316 and SS 304 options with Polyester or Nylon coating allows us to choose based on specific corrosive environment requirements. Very versatile product line.

Procurement Head, Ship & Marine

The UV resistant coating protects the ties in our outdoor utility installations. After two years of sun exposure, the coating still looks and performs like new.

Field Engineer, Utility Services

Connect with our technical experts for personalized metal tooth tie solutions for your specific industry requirements.

Contact our team for product inquiries, technical support, or custom cable management solutions.

For immediate assistance, feel free to send us a quick email at [email protected] or call us at +91-22-22082525 to discuss your customized cable tie and wiring accessory requirements.

For immediate assistance, feel free to send us a quick email at [email protected] or call us at +91-22-22082525 to discuss your customized cable tie and wiring accessory requirements.