Perfect for Cable Identification

The outside tag ties have been perfect for our electrical installations. The ability to identify and secure cable bundles in one step has streamlined our operations significantly.

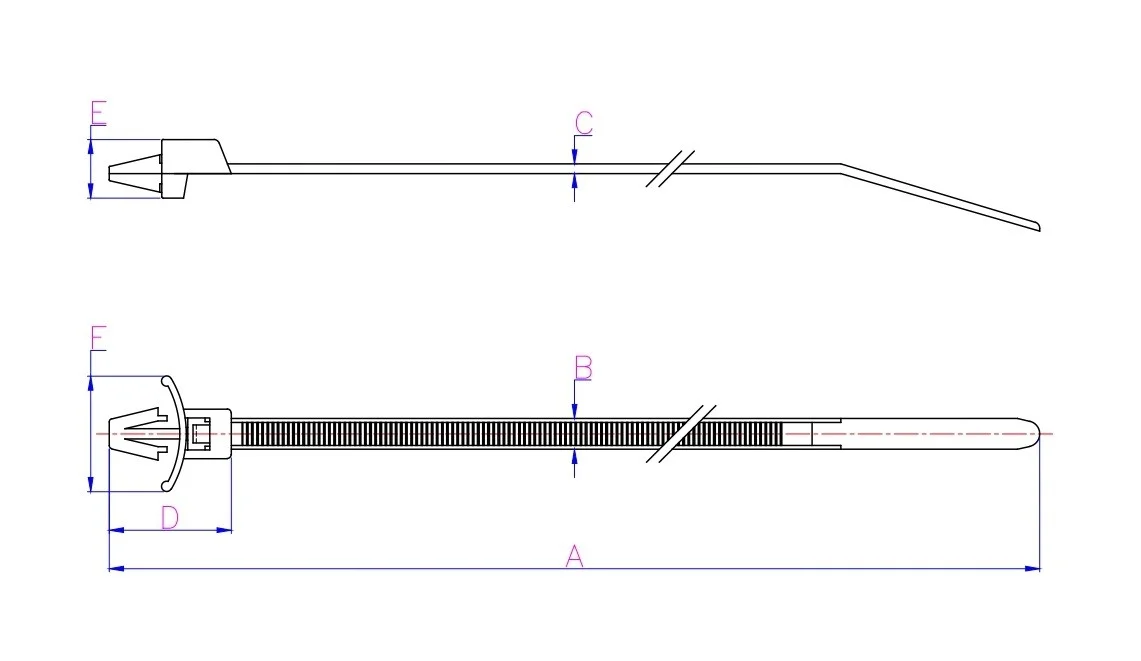

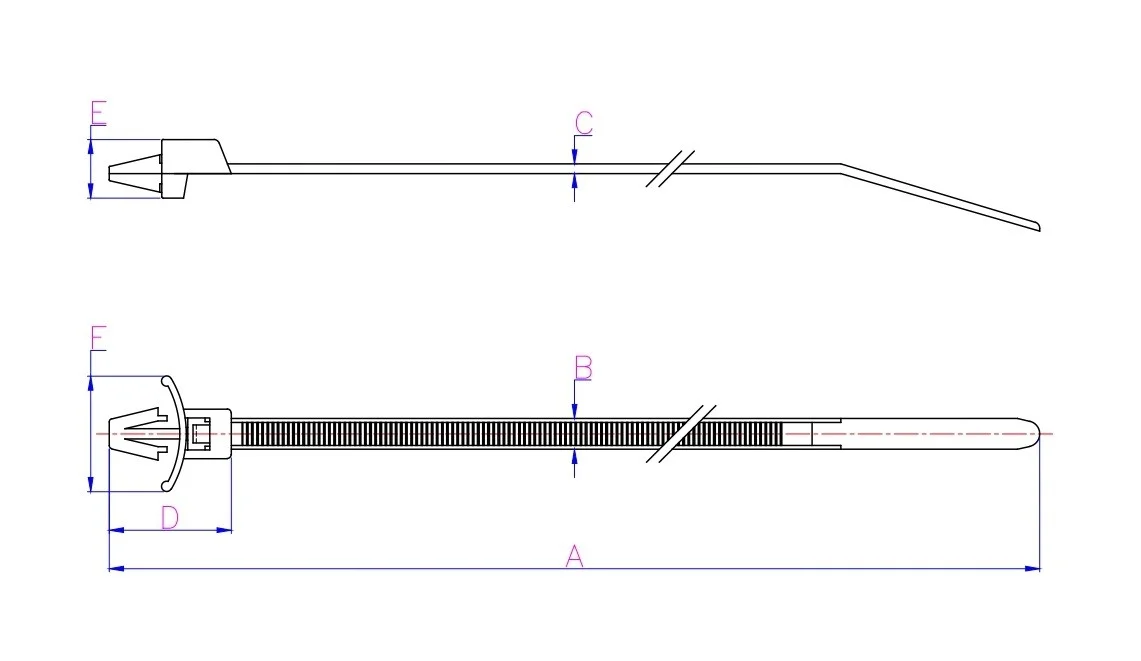

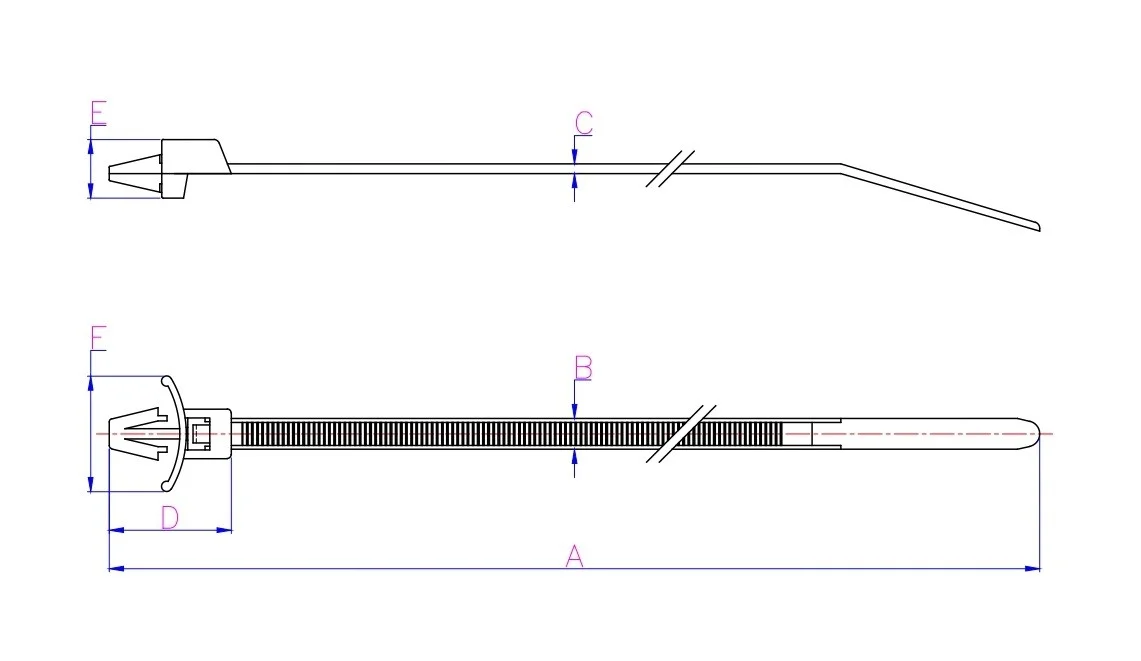

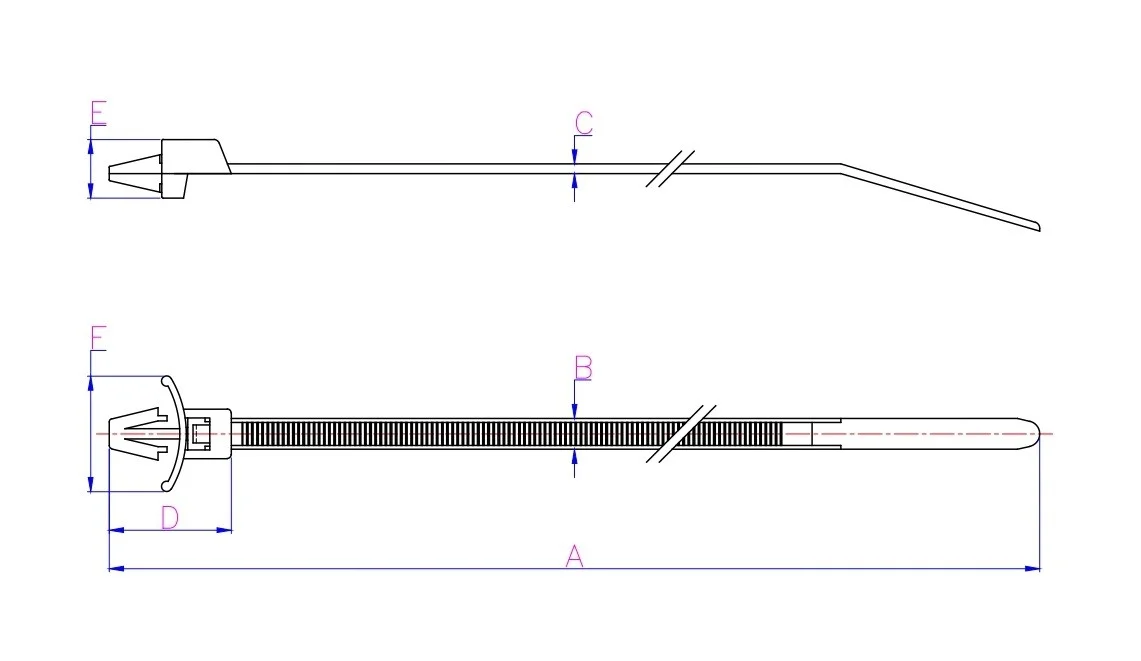

Outside Push Mount Tie

Price Available on Request

Comprehensive range of Outside Push Mount Tie with varying lengths, widths, and tensile strengths for diverse applications.

One-piece construction design eliminates the need for screws or adhesive mounts. Push mount tie head easily presses into pre-drilled holes for fast cable mounting by hand.

Wing design specifically engineered for harness assembly applications where constant vibration occurs, ideal for automobile, white goods, and electronics industries.

Simple hand installation with no special tools needed. Securely holds wire bunches on chassis of vehicles, ACs, coolers, and other white goods applications.

Operating temperature from -40°C to +85°C with UL 94V-2 flammability rating ensures reliable performance in automotive and appliance environments.

Available in 7 sizes from 100mm to 205mm length, with tensile strengths from 8kg to 22kg, accommodating bundle diameters from 21mm to 50mm and hole diameters from 4.5mm to 6.4mm.

Available in Natural and Black colors made from high-strength Nylon 66 for excellent durability and chemical resistance in various mounting applications.

Subscribe to receive our latest product updates and technical specifications directly.

For indoor cable bunching and durable locking in adverse conditions like humidity, heat, cold, vibration & external shocks.

The outside tag ties have been perfect for our electrical installations. The ability to identify and secure cable bundles in one step has streamlined our operations significantly.

Electrical Engineer, Power Systems Ltd

We use laser marking on these tag ties for our networking installations. The permanent identification is clear and professional, exactly what we needed for our data center projects.

Network Manager, Data Solutions Inc

For our packaging operations, these outside tag ties provide the perfect solution for securing and identifying different product bundles with UL 94V-2 safety rating.

Operations Manager, Pack Solutions

The ability to use both laser marking for permanent identification and manual marking with pens for temporary needs gives us the flexibility we require in our telecom installations.

Project Manager, Telecom Networks

The consistent packaging of 100 pcs per bag makes inventory management easy, and the Nylon 66 material quality is exactly what we expect from professional-grade products.

Procurement Manager, Industrial Solutions

We appreciate that these can be installed by hand or using TT3/TT4 tools. The flexibility allows us to choose the best installation method for each project requirement.

Installation Manager, Electronics Manufacturing

Connect with our technical experts for personalized metal tooth tie solutions for your specific industry requirements.

Contact our team for product inquiries, technical support, or custom cable management solutions.

For immediate assistance, feel free to send us a quick email at [email protected] or call us at +91-22-22082525 to discuss your customized cable tie and wiring accessory requirements.

For immediate assistance, feel free to send us a quick email at [email protected] or call us at +91-22-22082525 to discuss your customized cable tie and wiring accessory requirements.