Perfect for High-Temperature Applications

These heat stabilised ties perform excellently in our locomotive electrical systems. They maintain their strength even in extreme heat conditions near engine compartments.

Heat Stabilised Metal Tooth Ties

Price Available on Request

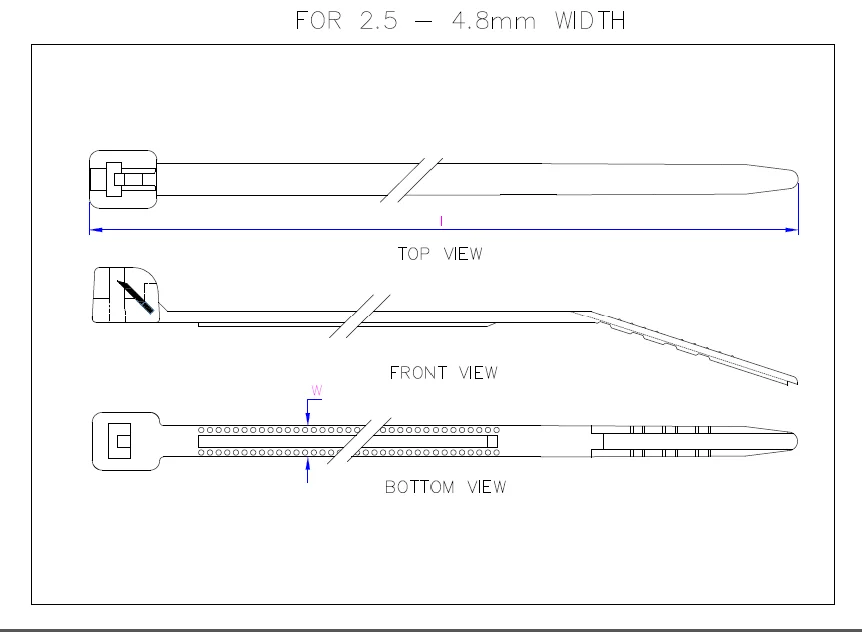

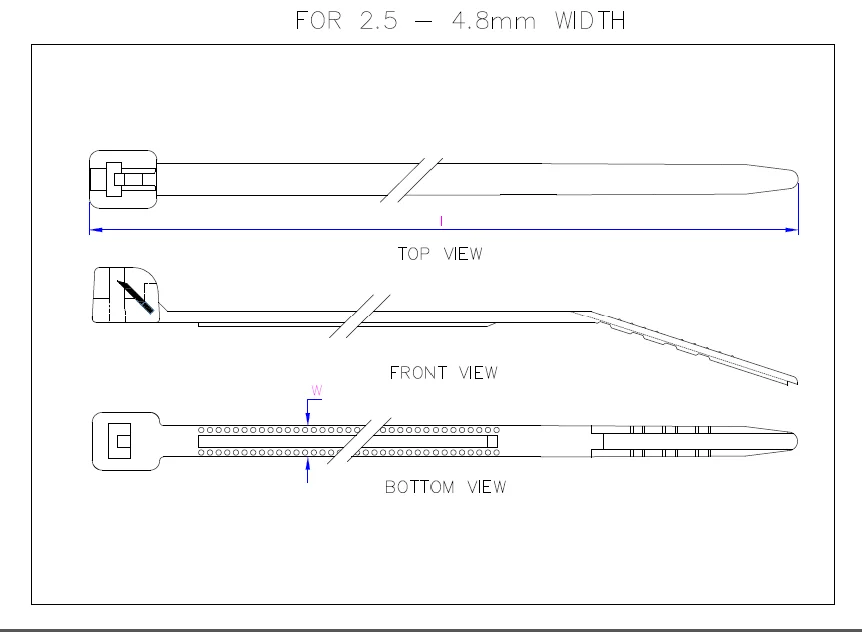

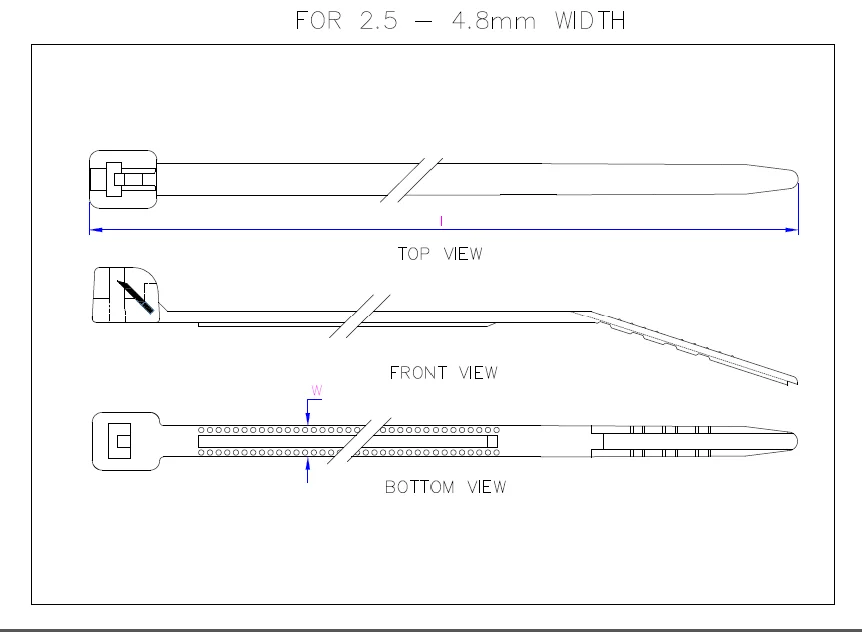

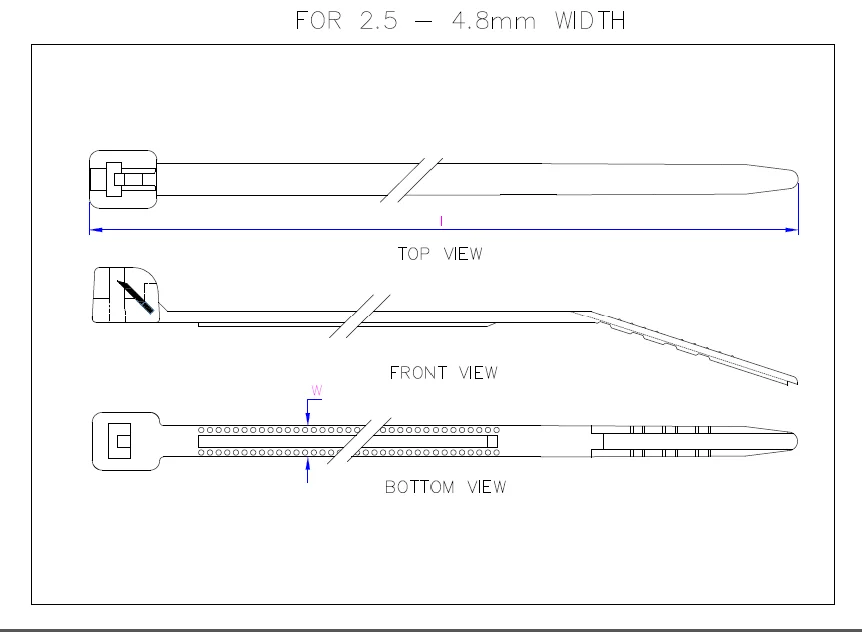

Comprehensive range of Heat Stabilised Metal Tooth Ties with varying lengths, widths, and tensile strengths for diverse wire bundling applications.

Operating temperature range from -40°C to +125°C ensures reliable performance in the most demanding high-temperature and extreme cold conditions.

Corrosion proof, non-magnetic steel tooth firmly anchors inside the cable tie body with positive locking, ensuring no slippage in adverse conditions.

Engineered for durable locking in adverse conditions including humidity, heat, cold, vibration and external shocks with zero chances of slippage.

Made from Nylon 66 high-performance polyamide material, specifically formulated for extreme temperature applications and long-term reliability.

Suitable for demanding applications in aviation, locomotive, and windmill industries where reliability and performance are critical requirements.

Available in convenient 100-piece packets with precise tolerances (Length ±4mm, Width ±0.4mm) for consistent quality and easy inventory management.

Subscribe to receive our latest product updates and technical specifications directly.

For indoor cable bunching and durable locking in adverse conditions like humidity, heat, cold, vibration & external shocks.

These heat stabilised ties perform excellently in our locomotive electrical systems. They maintain their strength even in extreme heat conditions near engine compartments.

Maintenance Manager, Railway Systems

The metal tooth locking mechanism is outstanding. We use these ties in aircraft wire harnesses and they've never failed despite constant vibration and temperature fluctuations.

Quality Engineer, Aviation Manufacturing

For windmill nacelle installations, these heat stabilised ties are essential. They handle the temperature extremes and weather conditions without degrading over time.

Installation Supervisor, Renewable Energy

The variety of widths and lengths available means we can use these ties for everything from small control cables to large power cable bundles in industrial equipment.

Electrical Supervisor, Heavy Manufacturing

The Nylon 66 construction is clearly premium quality. These ties don't become brittle or lose strength even after years of exposure to high temperatures in our process environment.

Maintenance Lead, Process Industry

The non-magnetic, corrosion-proof steel tooth is a game changer. We install these in harsh marine environments on offshore platforms and they hold up perfectly.

Project Manager, Offshore Engineering

Connect with our technical experts for personalized metal tooth tie solutions for your specific industry requirements.

Contact our team for product inquiries, technical support, or custom cable management solutions.

For immediate assistance, feel free to send us a quick email at [email protected] or call us at +91-22-22082525 to discuss your customized cable tie and wiring accessory requirements.

For immediate assistance, feel free to send us a quick email at [email protected] or call us at +91-22-22082525 to discuss your customized cable tie and wiring accessory requirements.